![MKS sports Pierino Persico,<strong><a href=]() MKS sports president of the Persico Group Photos on this page: Courtesy of the Persico Group" src="https://www.globaltimes.cn/Portals/0/attachment/2025/2025-04-09/997fc568-9106-4f7b-b038-b761a6d5cd81.jpeg" />

MKS sports president of the Persico Group Photos on this page: Courtesy of the Persico Group" src="https://www.globaltimes.cn/Portals/0/attachment/2025/2025-04-09/997fc568-9106-4f7b-b038-b761a6d5cd81.jpeg" />Pierino Persico, president of the Persico Group Photos: Courtesy of the Persico Group

Mobility is evolving, centered around sustainability, eco-friendly, electric and interactive vehicles, hydrogen fuel, and many other new solutions that just a few years ago seemed like a pipe dream. Original Equipment Manufacturers (OEMs), Tier 1 suppliers, and all companies involved in the automotive supply chain are working to find the best solutions for producing these new vehicles, such as complex, eco-friendly electronic devices. The Persico Group is directly involved in this evolution from many perspectives:

The company respects the environment and generates renewable electricity for its headquarters (located in Nembro, in the province of Bergamo, Italy) through solar and hydroelectric energy.

Additionally, the energy not directly produced by Persico comes from renewable sources.

The Persico Group is managing the requirements set by OEMs for the entire automotive production chain: an environmental sustainability plan that will involve the entire production process, creating zero-emission products.

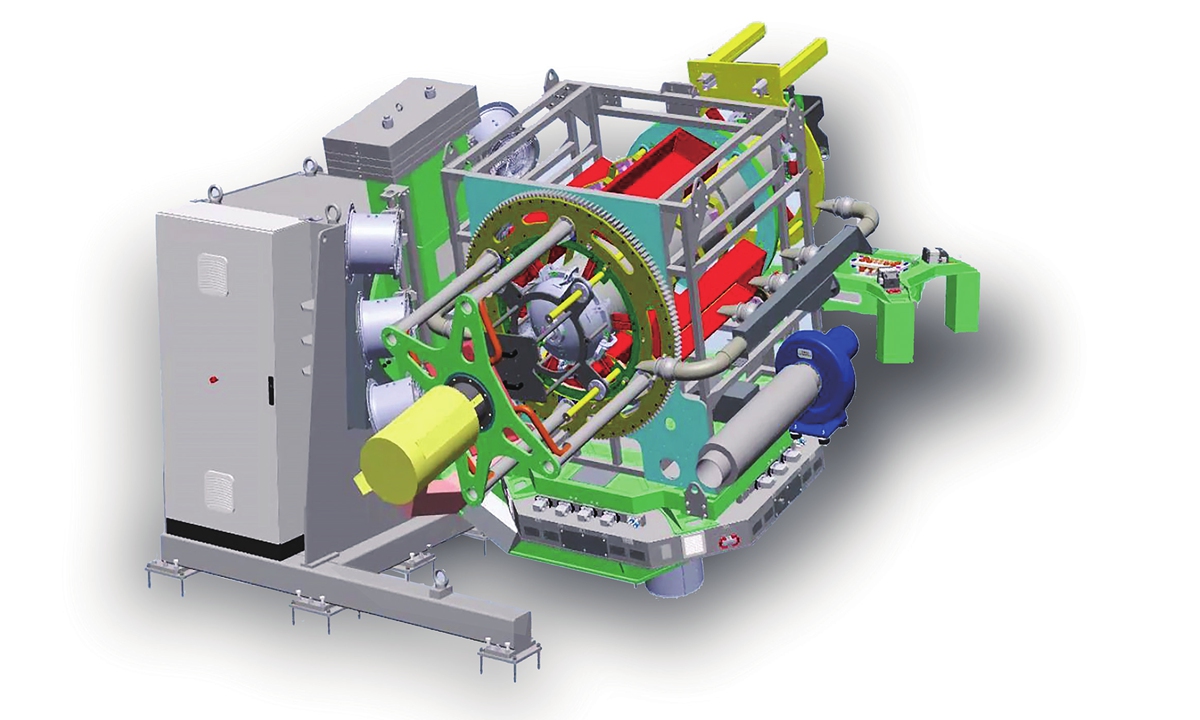

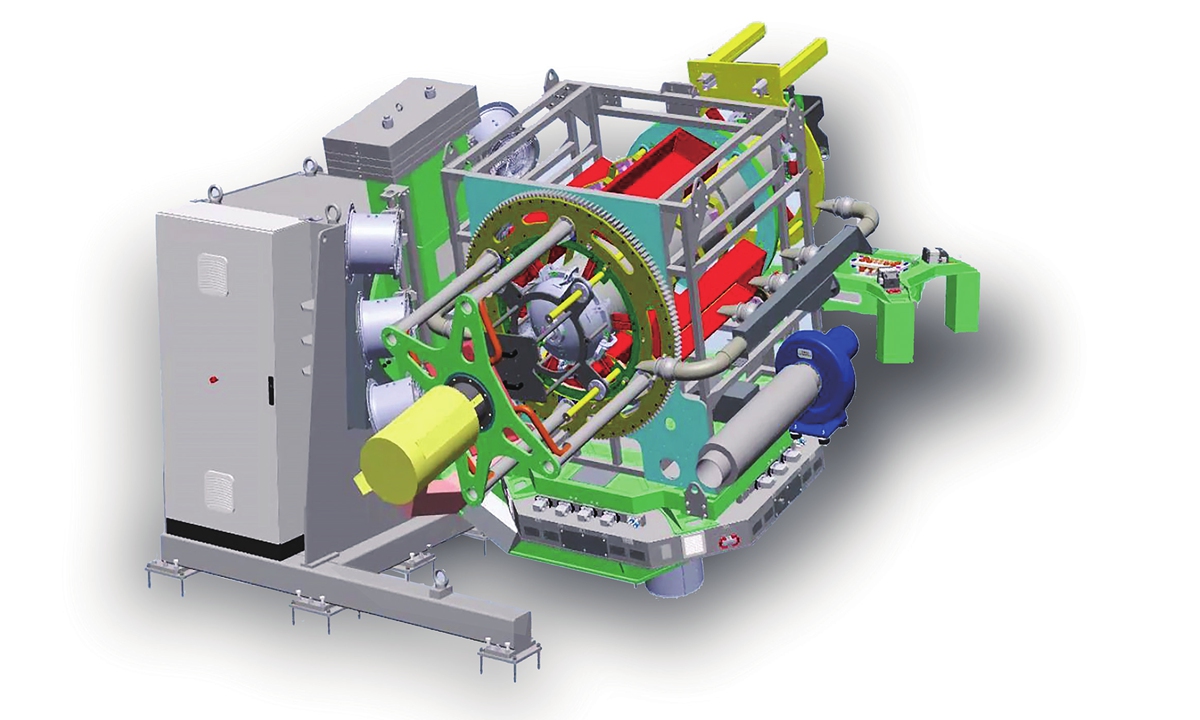

The company is addressing the current situation by offering alternatives to gas and raw material needs: For example, it has implemented SMART® technology for the production of plastic hollow bodies.

Persico develops tools and equipment for producing components for vehicles, such as hydrogen tank liners and battery covers for electric vehicles. The interest in using hydrogen in the transport sector is growing, not only for the significant effort put into developing solutions and technologies to enable its easy use, but also for creating components that simplify its installation in vehicles. One of the key aspects is hydrogen storage: Through this technology, the gas must be stored at a pressure of up to 700 bar in composite tanks made of carbon fiber with an internal polymer shell called a "liner." Hydrogen tanks are subjected to mechanical and thermal loads (gas heating when the tank is full).

At the same time, the polymer lining must not bend or collapse when the gas inside the tank is discharged. The goal is to create lightweight and compact tanks that offer high levels of strength and safety.

In recent years, the Persico Group has worked with OEMs and Tier 1 suppliers to develop a composite tank for hydrogen storage.

Thanks to its innovative design, the weight of the tank and its accessories can be reduced by a third compared to traditional steel cylindrical tanks.

The adaptable shape allows for a high degree of flexibility, enabling significant energy savings.

Furthermore, the accessory systems are integrated into the tank container, reducing space in the vehicle and making maintenance easier.

The internal tank is designed on a modular basis to simplify the manufacturing process.

Various technologies are used to produce polymer linings for hydrogen tanks, such as injection molding, blow molding, and rotational molding.

Smart H2 of the Persico Group

Six paths of compact multinationalFounded in 1976 by Pierino Persico, who is still the president of the group, the Persico Group is an Italian multinational primarily engaged in the automotive, rotomolding (or rotational molding), and marine sectors, providing a full range of services: from conceptual design to engineering, prototyping, model production, molds, automation systems, and turnkey yachts.

Persico also operates in other sectors, including aerospace, medical and architecture.

With its headquarters and main production facilities in Italy, Persico has key production and commercial units in the United States, Mexico, Germany, and China to serve its global clients.

Approaching its 50th anniversary, with the contribution of the founder's children Alessandra, Claudia, and Marcello, the company is organized into six business units (BUs):

The BU Automotive Interiors, which provides increasingly sophisticated systems for producing interior trim parts for cars and industrial vehicles.

The BU Automotive Compression, specializing in molds, presses, and systems for manufacturing external vehicle parts.

The BU Rotomolding, which supplies molds for the traditional rotational market and automated systems for direct mold heating.

The BU Machinery, which, with a team of highly qualified engineers, can offer any level of automation for all the technological processes provided by Persico.

Persico Marine builds custom racing yachts for the world's most renowned teams and private owners, and provides molds and frames for the production of motorboats and sailboats. Since 2023, Persico Marine has been ISO 9001 certified for advanced composite molding for the aerospace and aeronautics industry.

Bielomatik, a world leader in the supply of plastic welding systems, offering a range of solutions based on the type of welding required. In 2024, the group achieved a turnover of 240 million euros ($265 million) with 850 employees internationally and exports more than 80 percent of its production.