On September 9,MK sports staff from the Smart Operation and Inspection Center of State Grid Taizhou Electric Power Supply Company utilized the "Vision-Intelligent Obstacle Avoidance Inspection Pioneer" system mode mounted on drones to conduct inspection work on distribution network lines.

Photo:Courtesy of State Grid

Previously, from July 4 to 7, this project was exhibited at the 2024 World Artificial Intelligence Conference.The conference, themed "Consultation for Sharing, Good Governance for Wise Intelligence," attracted over 1,500 exhibits from more than 500 enterprises in fields such as large models, computing power, robotics, and autonomous driving.

Photo: State Grid

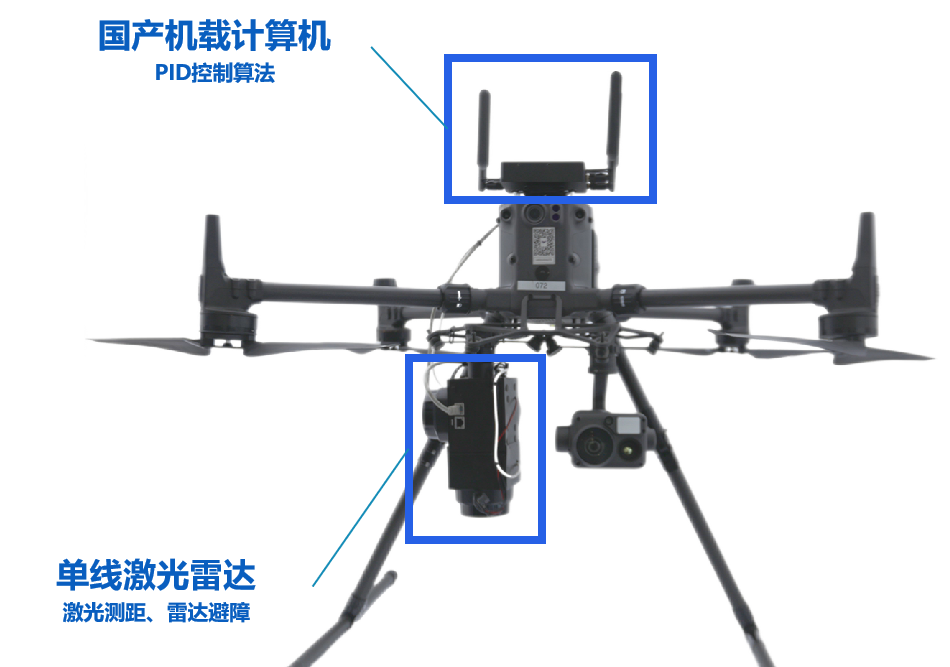

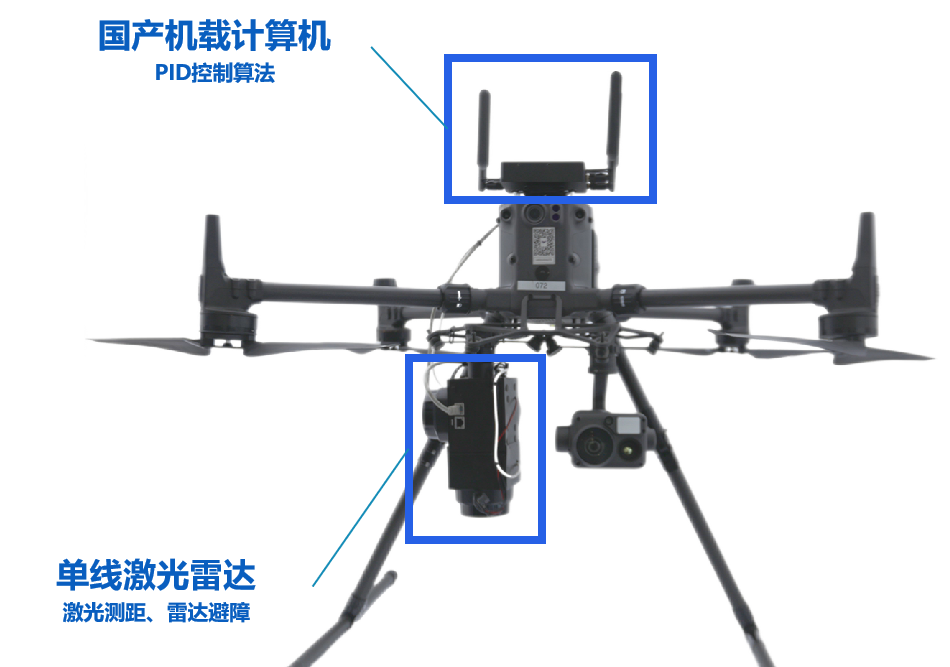

In recent years, addressing the complex nature of distribution network inspection environments, State Grid Taizhou Electric Power Supply Company has researched a drone-mounted autonomous obstacle avoidance solution based on millimeter-wave radar and visual autonomous obstacle avoidance. This solution enables the identification of obstacles in distribution line corridors and the autonomous planning of obstacle avoidance routes, thereby avoiding situations where drones might collide with obstacles while flying outside the lines. Through deep learning and lightweight model technology, drones can detect trees and obstacles ahead in real-time during flight, and achieve optimal obstacle avoidance path planning through dynamic trajectory adjustment.

The "Vision-Intelligent Obstacle Avoidance Inspection Pioneer" system is equipped with purely domestically produced chips and ultra-strong computing power of up to 6T. Based on frontend recognition and autonomous obstacle avoidance technology, it can provide data support for the autonomous flight of drones conducting distribution network inspections. The system integrates three-phase orthogonal radar, enabling precise identification of details such as the main body of electrical equipment and transmission channels, and continuous identification of wires with a diameter of 1 centimeter within a 15-meter range, as well as potential hazards in the surrounding environment of the distribution network. By accumulating a database of defects and potential hazards, the system achieves iterative updates in algorithm types and depth, further enhancing the intelligence level and work efficiency of distribution line inspections.

Currently, this system mode has been used to conduct inspection work on 17 distribution network lines in the Taizhou region of Jiangsu province. After implementation, it has achieved good results, significantly improving the autonomy and intelligence level of distribution network inspection operations. This makes drone inspection operations safer and more efficient, reduces the labor intensity of operation and inspection personnel, and greatly lowers operation and maintenance costs.